Excitement About Curtain Wall Spandrel Panel Detail

By knowing surface area temperature levels, Pie has the ability to determine under which problems condensation will certainly occur, in addition to identify shift points at which condensation will certainly not establish, making it much easier to anticipate and also remediate - insulated metal spandrel panels. In enhancement, different configurations can be modeled to maximize interior surface area temperatures. Setting up back pans into the spandrel infill glazing pocket, which are aired vent to the exterior with insulation outboard of the frying pan, advertises increased indoor surface temperatures with the added benefit of minimizing heat transfer through the spandrel infill.

It is possible to make best use of interior surface temperature levels by removing making use of insulation at the spandrel infill place. Keep in mind if you make without insulation at spandrel infill areas, there will be a higher power loss through the assembly and for that reason larger COOLING AND HEATING warm loads. At Pie, we can help you each step of the method, whether you recently found condensation and are looking for removal and monitoring options, or whether you are making a building and also purpose to reduce the potential for condensation at spandrel infill locations.

Boost R-Values Without Compromising Layout! Glazing infill panels are made to be 'polished' into a light weight aluminum window system instead of glass. They use several benefits to designers as well as building owners looking for expense efficient as well as aesthetically pleasing choices for their buildings. Protected panels contain 3 various layers- a rigid insulation core sandwiched in between a finished concrete face as well as back.

Made use of as a window substitute, Synstone infill panels enhance the thermal effectiveness of window openings. This decreases the cost of possession by enabling cost savings on cooling and heating. Synstone infill panels contain non-asbestos glass fibre enhanced concrete faces with foam core insulation. Synstone infill panels can be made to R= 24 insulation value.

A Biased View of Roof Spandrel Panels

In traditional structure, the term "describes the about triangular room or surface area that is found in between a rounded number and also a rectangle-shaped boundary. It is believed to obtain from from the Old French word 'spandre', indicating to spread. Such can be discovered in a variety of scenarios: Much more lately, the term 'spandrel panel' has actually been utilized to describe built triangular panels utilized in roofing system building to separate areas under the roof covering, or to finish the gable end of a roofing system.

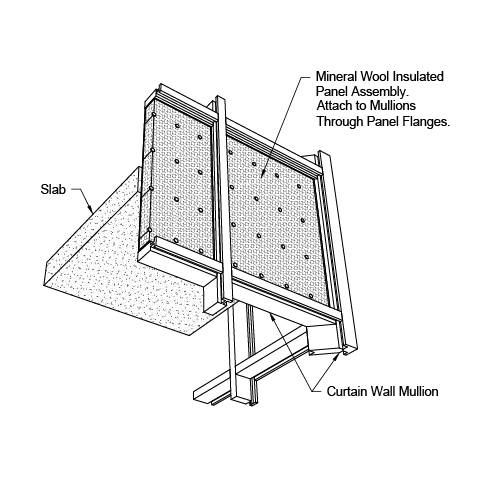

The term spandrel panel may likewise be utilized to describe cladding panels that load the area over the head of a home window on one floor as well as listed below the cill of the window on the next floor on high-rise structures. These panels conceal the flooring structure. If they are made from opaque or transparent glass, this might be described as spandrel glass.

It suggests that; "Spandrel panels can be offered both visual as well as useful functions. Like the remainder of the external wall, the panels are normally required to satisfy acoustic, thermal, wetness, and fire performance requirements. gable spandrel have a peek at this website panel. Such panels are not generally pack birthing yet are commonly developed to make up wind loading...

Where there is no details concerning the panel or there is uncertainty, it will be essential to check out the panel structure by example screening." Ref https://www.gov. insulated metal spandrel panels.uk/government/publications/advice-for-building-owners-on-spandrel-panelswindow-panelsinfill-panels-on-external-walls NB The term spandrel beam of light describes an exterior light beam that prolongs from one column to another, lugging an outside wall surface lots.

Glaz-Tech Industries introduces GlazeGuard 250WR as well as GlazeGuard1000 WR infill panels to additional offer added architectural remedies for store and window systems. Its durable and also attractive design adds with store applications and shielded systems. Glaz-Tech's infill panels provide several architectural advantages: GlazeGuard WR panels are very effective versus wetness breach as well as likewise perfect for installation more tips here due to its light-weight layout.

The 5-Minute Rule for Gable Spandrel Panel

With a number of various compositions as well as finish choices, GlazeGuard can give an economical choice to various other polishing remedies while still offering aesthetic passion and worth. Little or no upkeep is called for and most oil, dirt, oil and other foreign material can be conveniently cleansed from the surface. Glaz-Tech stocks Metal Silver, Shasta White and also Standard Bronze.

Component Requirement (in) Metric (mm) Prefinished Distinctive Light Weight Aluminum Skins.010".254 viracon spandrel glass mm Prefinished Smooth Aluminum Skins.024".609 mm High Thickness Polypropylene Core 1/4" 6.00 mm Home Criterion (in) Metric (mm) Panel Weight.72 pounds/ feet 3.51 kg/ m Small Density 1/4" 6mm GlazeGuard 1000 WR is a composite panel for usage as a polishing infill made by laminating flooring 2 prefinished aluminum skins to substratums of high thickness polypropylene.